Bushel baskets became popular in the citrus industry in the 1920s, first as a way to ship oranges and grapefruits from Florida and then as a way to sell fruit in the grocery. Farmers would sell peas, peaches and other produce in bushel baskets. Now, many of us typically reach for a plastic bag to gather produce to take home from the store.

The name bushel is a literal measurement. It is equal to 4 pecks, 32 quarts or 64 pints.

Dresden & Company’s new Bushel Basket and Baby Bushel Basket take their names from those early versions, but that’s where their similarities end (especially in capacity). Available throughout September, our baskets are full of color and other details that make them unique. The Maple Leaf Orange or Maple Leaf Green body of the basket is accented with Charcoal shoestring and trim. The baskets both have an inverted bottom, which was originally created to allow air to circulate and keep the contents of the baskets fresh longer. One of the most interesting attributes of these baskets is the softly squared handle that gives our version a new, more modern look.

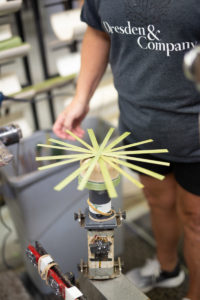

On a recent visit to the D&Co. Workshop, we spoke with Basketmaker Lisa McMullen about the process involved in crafting these unique baskets. Lisa said it all begins with putting the inside band onto the form. Next is laying the splints out evenly over the inverted Baby Bushel Basket form. The specifications for this basket require 4-3/8″ splints and 4-1/2″ splints. Once the splints are perfectly aligned, she uses a screw-down to depress the material into

the inverted form.

The next step is to begin weaving with shoestring size material. There are a total of 6 rows of very tightly woven material used in this process. This is what ensures that the basket will retain its inverted bottom, even when removed from the weaving form.

Once the shoestring is complete, 4 rows of 3/8″ weave are woven onto the basket using the traditional over/under method. This all culminates with the application of the top band and trim strip. Once the band is firmly in place, Lisa gives the basket a “hair cut,” meaning she trims the excess upsplint material from above the band.

Next, two holes are drilled on either side of the basket where the handle will be affixed. Lisa uses a wood wheel as a spacer between the handle and the basket, then adds nickel rivets to secure the handle in place. After careful inspection of the completed basket, Lisa proudly signs her name and dates her newest creation. As our conversation with Lisa comes to a close, she shares that she prefers making small baskets like the Baby Bushel.

We know she’s not alone in loving small baskets as many of you are loving the Baby Bushel.